An Overview of My Senior Project

My high school required students to spend their senior year working with a group on an engineering design project of their choice. This project served as one of the most formative experiences in my educational career thus far. I learned and taught myself numerous new skills, and learned what it meant to work with the same group of people long term. This post is an overview of the project my group and I created, and what I learned from it.

Project Concept

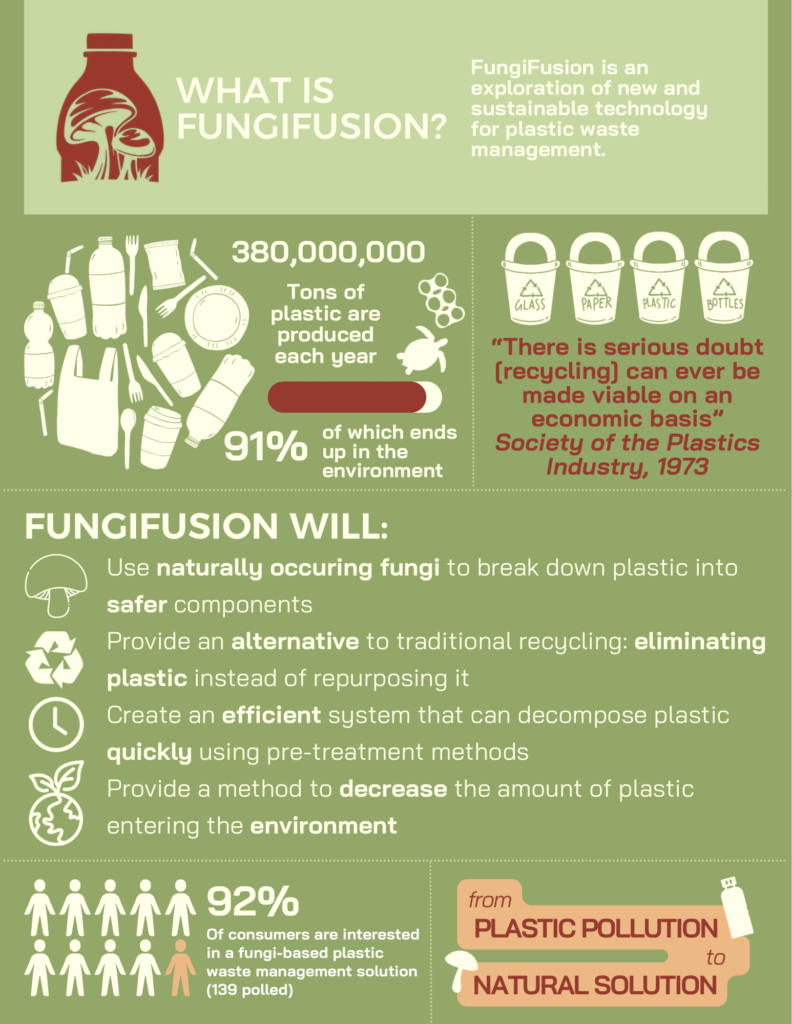

I had the idea for the project that I ultimately worked on, and gathered my group around the idea. I read online that many species of fungi had been found to be able to break down plastic; completely break it down, at a molecular level, leaving behind only its safer components. My initial thought was: surely someone is developing these into a solution for plastic waste. But to my surprise, no one had began innovating from this discovery. Thus the idea for FungiFusion was born. Use cheap and naturally occurring fungi to break down plastic that isn’t getting recycled.

As the project went on, and we learned more about the problem, we found it to be much larger than we had initially realized. Recycling truly isn’t working. Only 9% of all plastic gets recycled, and most plastics can only be recycled one time before they have to be thrown away. The cost of recycling is ridiculous. We found that our relatively small county loses $1.9 million per year on “recycling inefficiencies.” Additionally, recycling creates microplastics, which are estimated to be present in 80% of people’s bodies. Microplastics are passed from mother to child, so this number will likely go up as time goes on. Microplastics cause cancer, immune system disruption, brain damage, headaches, digestive issues, and more. This is a growing problem, so innovative solutions are incredibly important.

In our research we found that plastic exposed to UV light, and then introduced to fungus breaks down much faster. Breaking the plastic into smaller pieces also increases efficiency, because of the increased surface area for the fungus to grow on. We implemented both of these into our solution, because fungal degradation of the plastic is a relatively slow process. It can take anywhere from a few months, to a few years, but the science really isn’t there yet. While this seems like a long time, plastic left in the environment takes centuries to degrade, so this really is an improvement.

Building Our Prototype

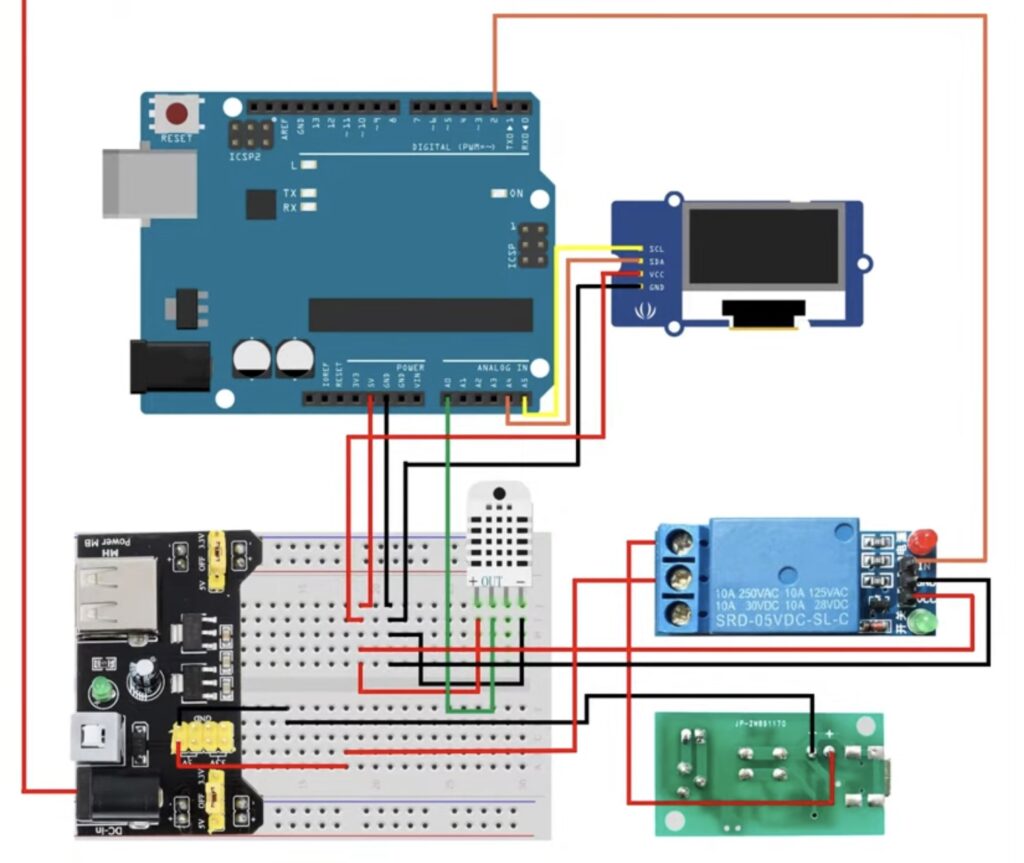

Over the course of the year, we iterated and designed a prototype to prove our concept works at a very small scale. While there were many iterations to our design, we ultimately landed on a three step process. Step 1: A small plastic shredder (which we built from a kit). Step 2: A UV photodegradation chamber (which we designed and built). Step 3: A fungal growth chamber (also designed and built by us). The fungal growth chamber is sealed and humidity controlled. In terms of contribution to the prototype, I was largely responsible for the electronics and software for the humidity controller. I taught myself electronics and Arduino code for this project.

Soft Skills

I served as the point of contact for the project group, because I wanted to use the project as an opportunity to develop my networking skills. As a part of the project, we had to acquire funding for our prototype. I cold-called an engineering professional who ultimately donated $2000 for the creation of our prototype. We also had to secure mentors in a field relevant to our idea. I cold emailed one of the leading mycology experts in the country, and he agreed to mentor us, and we kept up a relationship with him and his students throughout the year. I was also in charge of developing the project website, which is one of the contributions I’m most proud of. I think it looks great, and has tons of information about the work we did, for anyone curious to know more. Visit us at fungifusion.org.

Lab Research

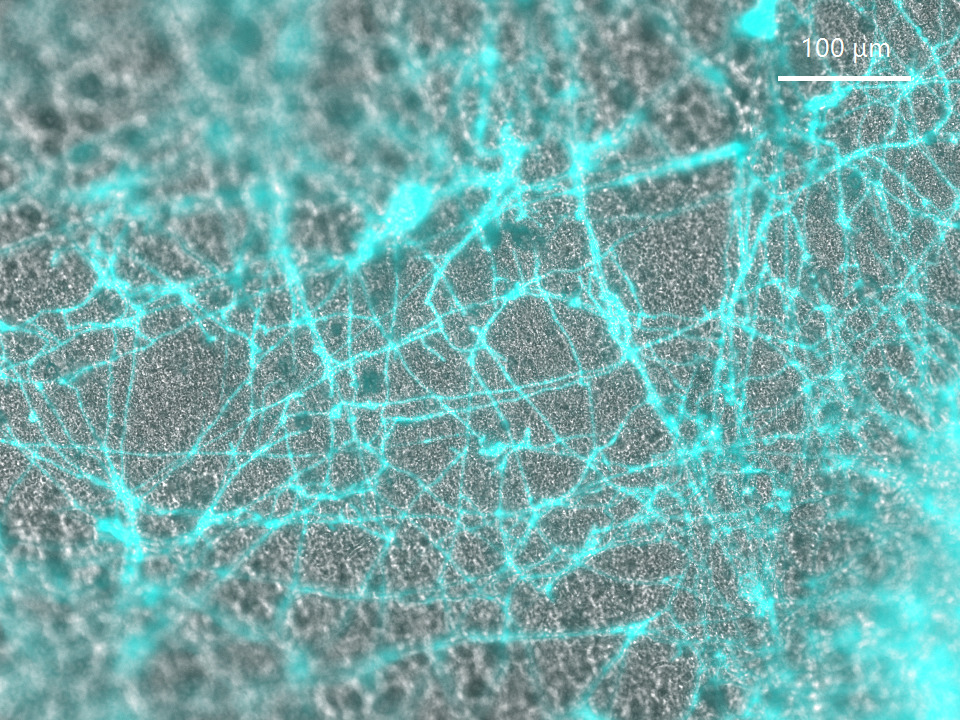

As a part of our testing process, we ran some amateur experiments in the Carter Lab on the campus of UNC Charlotte. As someone who wants to do scientific research for a living one day, this was incredibly insightful for me. I learned that I enjoy being in a lab, and many of the small tasks that composed our research process. At the end of our 8 week testing period, we found microscopic degradation on the plastic pieces that had been exposed to both fungus and UV light, which proved our idea was viable.

Results

My team won first place in our school’s senior design expo, which is an incredibly competitive day of presentations judged by a panel of engineering professors and industry professionals. We won a small prize and our team name will be on a trophy displayed in the school. We also submitted our project to the KnoPro “Young Entrepreneurs” competition, and won first place, with a cash prize of $5000. This was a national competition for any high schooler that wanted to enter.

Thank you for reading about the work I did this year. I’m a student exploring the world and documenting my thoughts on this site. Learn more about me, or view my other projects.